Hello @MingboPeng

Thank you for your hard work

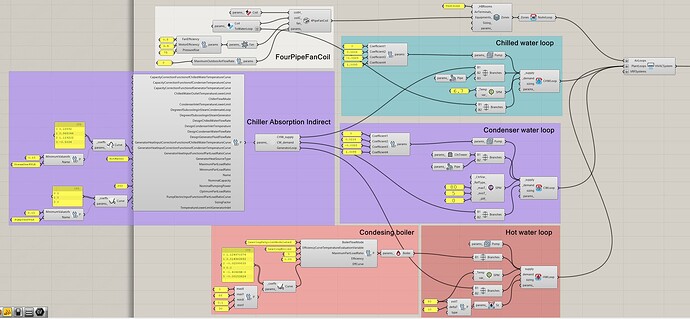

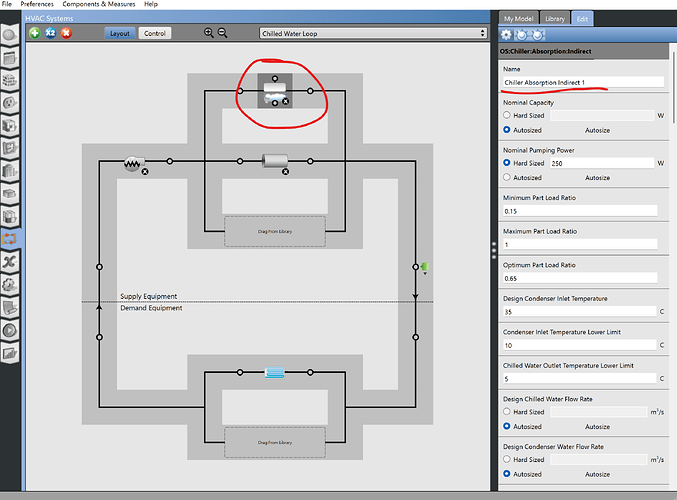

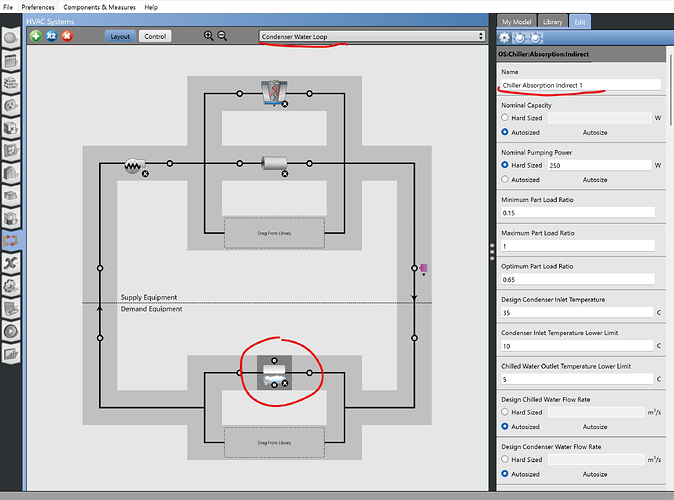

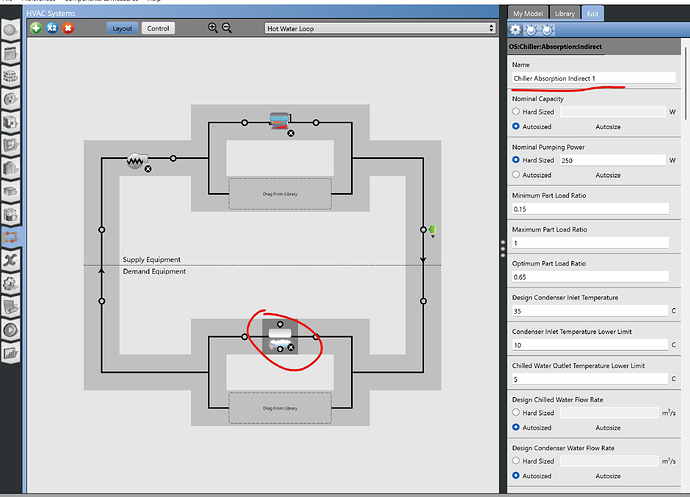

I want to make a custom HVAC system including an indirect absorption chiller. However, I couldn’t get any information about the indirect absorption chiller anywhere. When referring to the Energy Plus document(Group – Plant Equipment: Input Output Reference — EnergyPlus 24.2), I couldn’t find any such information in the ironbug. It’s not the indirect absorption chiller in the ironbug yet?

Can it be implemented using the string below? If implemented, I wonder how to connect ‘Gener Inlet Node Name’ and ‘Gener Outlet Node Name’ using hot water or steam.

Thank you for your kind reply in advance ![]()

Chiller:Absorption:Indirect,

Big Chiller, !- Chiller Name

100000, !- Nominal Capacity {W}

250, !- Nominal Pumping Power {W}

Big Chiller Inlet Node, !- Evaporator Inlet Node Name

Big Chiller Outlet Node, !- Evaporator Outlet Node Name

Big Chiller Condenser Inlet Node, !- Condenser Inlet Node Name

Big Chiller Condenser Outlet Node, !- Condenser Outlet Node Name

0.15, !- Minimum Part Load Ratio

1.0, !- Maximum Part Load Ratio

0.65, !- Opt Part Load Ratio

35.0, !- Temp Design Condenser Inlet {C}

10.0, !- Temp Lower Limit Condenser Inlet {C}

5.0, !- Chilled Water Outlet Temperature Lower Limit {C}

0.0011, !- Design Chilled Water Flow Rate {m3/s}

0.0011, !- Design Condenser Water Flow Rate {m3/s}

VariableFlow, !- Chiller Flow Mode

SteamUseFPLR, !- Generator Heat Input function of part-load ratio curve name

PumpUseFPLR, !- Pump Electric Input function of part-load ratio curve name

AbsorberSteamInletNode, !- Generator Inlet Node Name

AbsorberSteamOutletNode, !- Generator Outlet Node Name

CAPfCOND, !- Capacity Correction function of condenser temperature curve name

CAPfEVAP, !- Capacity Correction function of evaporator temperature curve name

, !- Capacity Correction function of generator temperature curve name

SteamFCondTemp, !- Generator Heat Input Correction function of condenser temperature curve name

SteamFEvapTemp, !- Generator Heat Input Correction function of evaporator temperature curve name

Steam, !- Generator Heat Source Type

autosize, !- Design Generator Volumetric Fluid Flow Rate {m3/s}

30.0, !- Temp Lower Limit Generator Inlet {C}

2.0, !- Degree of Subcooling in Steam Generator {C}

12.0; !- Degree of Subcooling in Steam Condensate Loop {C}