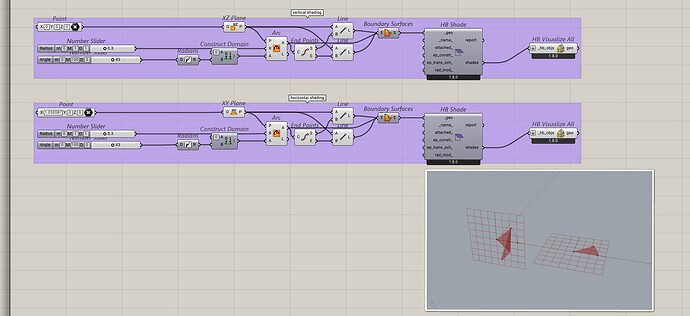

Hi there! I am currently working on a circular sector-shaped geometry for shading analysis in Honeybee, and I encountered the following problem, that honeybee cannot recognize certain combination of shape and orientation. I am using Rhino 8.16 and Ladybug 1.8 with unit in meters, and the test file is attached here: test_HB_shade.gh (51.0 KB)

Specifically, certain apparently planar sector-shaped geometry, when translated into honeybee shading object, will seem bent and sometimes will even result in irrelevant geometry. It looks like some meshing algorithm not functioning properly, and I am writing to ask the community, if anyone has also encountered this problem and how it could be resolved.

Taking the circular sector shape as an example, what I found so far that might break the shading geometry includes:

- Too small radius (starts to affect around the scale of 0.3m).

- Too small angle (starts to affect around 10°).

- orientation of the shading device (in my limited test cases, vertical shading geometry is more likely to be broken than horizontal shading geometry, as seen in the following screenshot).

Possible failure pattern might include:

- Bent geometry (as seen above)

- pointy subsurface (as seen below)

- completely missing shading surface (resolved with finer tolerance, see discussion below)

- missing sub-surfaces of a theoretically closed Brep (example below)

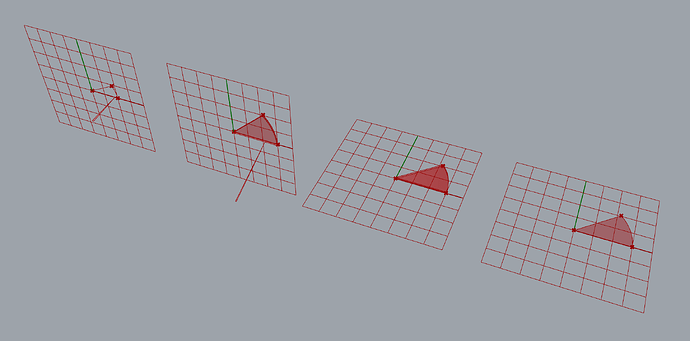

Note that linear and angular tolerance (accuracy) of model setting might affect the specific geometrical shape of failure, but could not completely resolve the problem. In the screenshot above, my tolerance is 0.01m and 1°; in the screenshot below, I changed my tolerance to be 0.00001m and 0.1° and restarted my Rhino. However, some issues still remain.

This image shows four shading object, from left to right (one can bake the visualized geometry to further check it in Rhino):

- vertical planar surface, when translating to shading object, the original object (outlined with curves and points in red) disappeared, leaving only with a spiky surface.

- vertical Brep, extruded from the abovementioned surface. The front surface of the extrusion is replaced with a pointy surface, and the whole Brep is not properly closed.

- horizontal Brep, extruded from a horizontal circular sector. The front surface and the back surface are sticked together.

- horizontal planar surface, this is translated successfully.