Hi there, I am running a desiccant wheel as shown in the image below (? icon) increasing the regen air temp with a heating coil seems to be having no effect on dehumdification performance. am i doing something wrong? ive tried a range of temperatures up to 150 degrees

Hi @MingboPeng,

could you please offer some assistance on this?

overall i am having trouble reaching a rh setpoint of 55% with an additional humidity ratio controlled coil. in theory the desiccant wheel should be able to get close to this on its own

After some investigation in Openstudio and the IDF editor, it seems that the DesiccantBalancedFlow heat exchanger is being added to the system “back to front” with its regeneration side on the OA stream. The regeneration inlet node is being set as the OA Outboard node.

There also appears to be no current way to model the dehumidifier in such a way that you can have it positioned as shown and attach a humidity control setpoint manager to the procces air outlet node within ironbug

@behnammmohseni Here is the issue i have posted about before. Currently i’m having to turn it around and assign a setpoint manager to it in the IDF editor

Certainly, here is a the HVAC system i am using

simplified desiccant system.gh (187.0 KB)

I really appreciate your assistance!

I am also having trouble getting the desiccant system to work effectively at anything over 0.01 ambient humidity ratio

Thank you for the file

Sorry I guess the file has missing geometries that I cannot run

And could you kindly paraphrase your questions and what are your challenges?

The issues i have been having have been the same across a few different building models that i have tested so i dont think the geometry is important for this issue.

For reference though the climate i am using is the one below. It has quiet high humidity.

AUS_NSW.Nowra.RAN.Air.Station.947500_RMY (1) - Copy.zip (173.5 KB)

other than what i have already mentioned I am struggling to get meaningful results from the desiccantBalancedFlow component.

I have modeled it alongside a condenser coil because it could not achieve the desired humidity ratio of 0.007 on its own (it does almost nothing to the maximum humidity ratio present in the zone with no humidity control).

after correctly configuring it in the IDF (in Ironbug it is modeled with its regen and procces sides on the wrong sides of the outdoor air system and needs to have its nodes changed around & The performance controller must also be altered to allow for higher regeneration temperatures in the IDF as this isn’t possible in ironbug.) I tested different regeneration temperatures which had no effect on its capacity to reduce the maximum humidity ratio but did offer some power savings in cooling so im assuming it is doing some work at lower ambient humidity ratios.

theoretically a higher regen temp should increase its effectiveness in dehumidification but this does not appear to be the case in my model. I cant figure out why

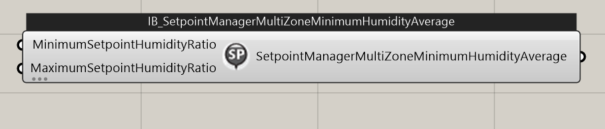

I think the setpoint manager you use is not complete, in addition to the temperature setpoint manager, you need to use humidity setpoint manager as well:

Due to the position of the desiccant wheel on the OA exhaust stream i have not been able to ensure the humidity setpoint is on the process air outlet node and controlling it correctly (i consistently get the message that there is no humidity control on the desiccant wheel). so i have been adding an extra maximum humidity ratio setpoint in ironbug and then attaching it to the process air outlet node straight in the IDF file which solves the issue

Hi @Nicholaskerr are you able to address it in the OpenStudio Application instead of post-processing the idf file? If yes, I might be able to help so that you don’t have to edit the idf file everytime.

Hi @MingboPeng, thanks for your reply.

Not that i am aware of. I can see that you can change the node names but you cannot manually define inlet and outlet nodes for components. It seems as though they are automatically assigned by the positioning of the component within the loop all i can do is drag the dehumidifier in to a new position within the outdoor air system but not turn it around.

I have asked some questions about desiccant systems on unmet hrs to see if they would be supported but did not get encouraging feedback.

It would be fantastic to be able to model them in a range of configurations given their energy saving potential. Currently the only place i have been able to attach it is to an OA system. Some systems have multiple air loops within them for secondary wheels, regeneration, and exhaust air.