Hey @wallen ,

This is correct in principle:

You are correct that the Ideal Air system is an All-Air system (like VAV) so it does both conditioning of ventilation air and management of space loads with the same air stream. This means that the cooling and heating values that you get in LBT-Grasshoppper when you simulate an Ideal Air System have both the ventilation load and the space load grouped into the same data.

However, because the Ideal Air System is simply telling you the thermal energy to be added/removed from the room + the ventilation air, getting these two thermal loads as separate terms out of EnergyPlus is pretty straightforward. It’s not like you are modeling a detailed VAV system and you are trying to disentangle which electricity or fuel was used for ventilation vs. space load (very difficult).

If you want to get separate values for the ideal load applied to the space vs the ideal load applied to the ventilation air, you do not need to run two separate simulations of energyplus (one with ventilation and one without). Nor do you need to approximate ventilation load with mCpDeltaT, which can miss the latent load and doesn’t let you account for things like heat recovery or economizers easily.

Instead, you can do it by just requesting EnergyPlus output variables that don’t lump the ideal air ventilation load together with the ideal air space load. If you look at the .rdd file that you get whenever you simulate a model with ideal air systems in it, you’ll see that there are a bunch of Ideal Air outputs to choose from:

The “Supply Air” outputs at the top are what they LBT-Grasshopper components parse in order to import the cooling and heating loads. So these account for all parts of the ideal air system all together (including space loads, outdoor air loads and heat recovery). After these outputs, you will see that you have “Zone” outputs, “Outdoor Air” outputs, and “Heat Recovery” outputs. The “Zone” outputs give you the space loads without accounting for any ventilation air and the other two together give you the ventilation load.

If you are just looking to get the space/zone load separate from the ventilation loads (accounting for both outdoor air and heat recovery), this is the simplest way to do it:

separate_ideal_air_vent_and_space_load.gh (61.6 KB)

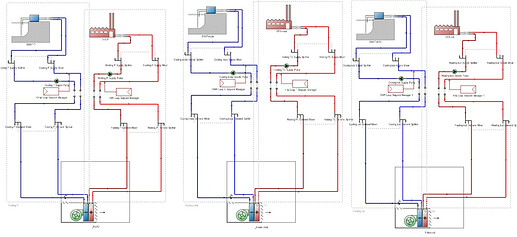

Granted, you will see that the ventilation load can go negative unlike the space load:

This is to be expected since, sometimes, the temperature of the outdoor air helps you heat or cool the space when you need it. Like when your room has a cooling load but the outdoor air is below room temperature. In this case, the introduction of outdoor air actually prevents you from needing to run the cooling coil to meet 100% of the space cooling load.

If this nuance of the ventilation load isn’t something that you want for your loads study, then you can just use the LB Apply Conditional Statement component to remove the hours with a negative load. But it’s an important thing to consider, particularly if the DOAS on your real building has an air-side economizer feature on it.

I hope that helps.