Hello,

I am trying to model an HVAC system in IronBug for a typical office/lab set up. This includes the following:

- AHU with thermal wheel supplies air at 18-20oC to meet fresh air ventilation rates only (no additional air for heating and cooling i.e. AHU coils only heat and cool the air to achieve supply air temperature and humidity)

- FCU at zone level to deal with zone loads

- Return air passes through the TW for heat recovery, no mixing pre thermal wheel i.e. (AHU A in image)

AHU B from my understanding is modelled by setting up an economizer - this is not what I desire in my simulation (i.e. no mixed air)

The problem I am facing currently is ensuring that the AHU cooling and heating coils do not end up conditioning additional air to help out the FCUs at zone level so to speak.

I also find that when I don’t apply an availability schedule (matching vent rates) to the dx coil, it seems to cool all the time, all year round (UK weather file going into HB Model to OSM)

What I’m trying to achieve:

- Limit the air loop flow rate so it tracks the actual required ventilation flow (not max).

- Ensure the AHU heating/cooling coils only treat the air to reach the required supply conditions, not to contribute to zone load balance.

- Keep FCUs as the sole zone load handler.

As a check, I would like to see the ‘fan mass flow rate’ to match the ‘requested ventilation mass flow rate’ - currently fan mass flow rate is constantly hitting max vent demand even when ventilation rate is below peak on my schedules.

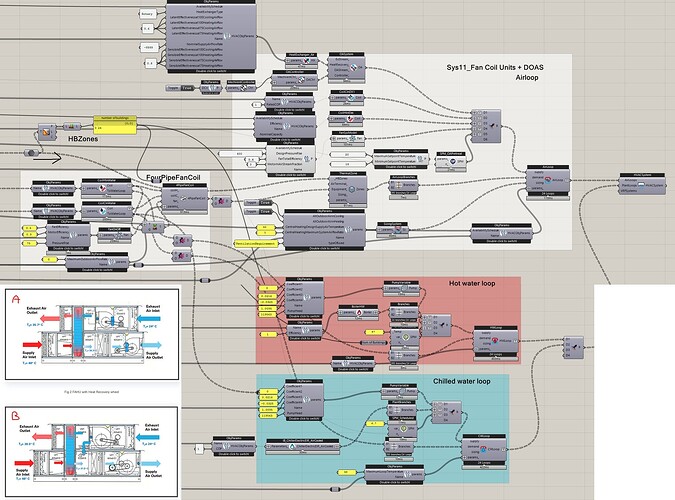

Here is my current set up to provide context. It is based on the DOAS and FCU arrangement.

The wires coming from off the screen are the building and room names for keeping track.

If anyone could advise me on how they would achieve this set up, any help would be much appreciated, thanks.