Thanks, Mingbo.

This definitely solved the issue. I also fixed the humidifier control.

The fluid issue still remains; despite me specifying the glychol, it has water as the medium. One thing I noticed is that I am actually trying to do a non-evaporative fluid cooler, which is in Open Studio but I guess is not in Ironbug yet. I do not know if this is a factor.

@Elliot_Glassman The reason that you cannot set its fluid type to Glycol is because there is a HotWaterBoiler in this loop’s supply side. I can set it successfully after I removed boiler from this loop.

I have added the non-evaporative fluid cooler in this update zip file. Please let me know if this works.

Ironbug_v0.0.12_20190707updates.zip (279.9 KB)

Hi Mingbo,

Thanks again for the quick response and update. Two questions:

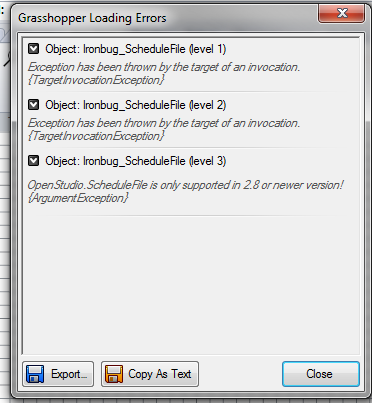

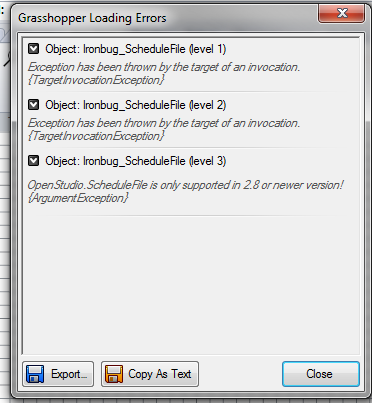

- I get this error when I open up Grasshopper:

Does not seem to affect anything I have in my model however.

- This seems kind of weird, but is it possible that there is a value hard coded for the design flow rate? I left it blank so it would autosize, but the simulation keeps having a fatal error and the IDF error file implies an inputted design flow rate of 1.388000E-003 m3/s. When I input a higher value, it runs.

Ah, I look forward to testing out 2.8 when I get through this exercise in 2.5!

The design flow rate in the fluid cooler. The error I get:

************* Beginning Plant Sizing Calculations

** Severe ** SizeFluidCooler: The combination of design input values did not allow the calculation of a

** ~~~ ** reasonable UA value. Review and revise design input values as appropriate. Specifying hard

** ~~~ ** sizes for some “autosizable” fields while autosizing other “autosizable” fields may be

** ~~~ ** contributing to this problem.

** ~~~ ** This model iterates on UA to find the heat transfer required to provide the design outlet

** ~~~ ** water temperature. Initially, the outlet water temperatures at high and low UA values are

** ~~~ ** calculated. The Design Exit Water Temperature should be between the outlet water

** ~~~ ** temperatures calculated at high and low UA values. If the Design Exit Water Temperature is

** ~~~ ** out of this range, the solution will not converge and UA will not be calculated.

** ~~~ ** The possible solutions could be to manually input adjusted water and/or air flow rates based

** ~~~ ** on the autosized values shown below or to adjust design fluid cooler air inlet dry-bulb temperature.

** ~~~ ** Plant:Sizing object inputs also influence these results (e.g. DeltaT and ExitTemp).

** ~~~ ** Inputs to the fluid cooler object:

** ~~~ ** Design Fluid Cooler Load [W] = 582060.00

** ~~~ ** Design Fluid Cooler Water Volume Flow Rate [m3/s] = 1.388000E-003

** ~~~ ** Design Fluid Cooler Air Volume Flow Rate [m3/s] = 139666.47

** ~~~ ** Design Fluid Cooler Air Inlet Dry-bulb Temp [C] = 35.00

** ~~~ ** Inputs to the plant sizing object:

** ~~~ ** Design Exit Water Temp [C] = 39.00

** ~~~ ** Loop Design Temperature Difference [C] = 11.00

** ~~~ ** Design Fluid Cooler Water Inlet Temp [C] = 51.67

** ~~~ ** Calculated water outlet temp at low UA [C] (UA = 58.21 W/K) = 51.50

** ~~~ ** Calculated water outlet temp at high UA [C] (UA = 582060.00 W/K) = 35.00

All the numbers are things I have input except for the Design Fluid Cooler Water Volume Flow Rate

@Elliot_Glassman , thanks for these details.

I wouldn’t be surprised that this is a bug from OpenStudio, as they had a similar issue before in CentralHeatPump.

I will do a quick test, and report it to OpenStudio team if needed.