First, I’d like to say great job with the Therm/honeybee interface - and thanks to LBNL for sharing. I watched all the tutorials online and I’m pretty sure I’m doing everything right, but I’m still not able to match ASHRAE 90.1’s U-values for steel frame walls (Table A3.3) and Wood-Frame Walls (Table A3.4). Has anyone tried this before and been successful? Here’s my process:

A few disclaimers first: I work exclusively in SI units (feet, BTU, etc) and I use R-values… even for the whole assembly. It’s easier for my brain to compute.

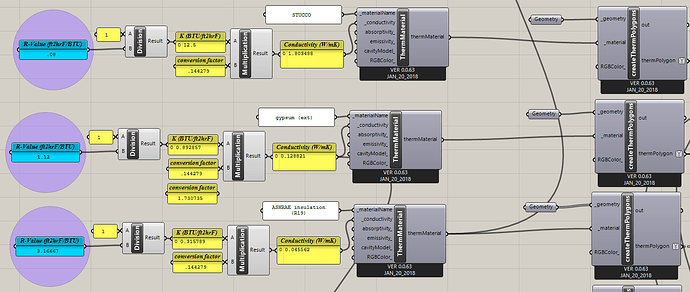

From the ASHRAE 90.1 User Manual (2007), I found that the “base wall assembly” referenced in these charts consists of (from exterior to interior):

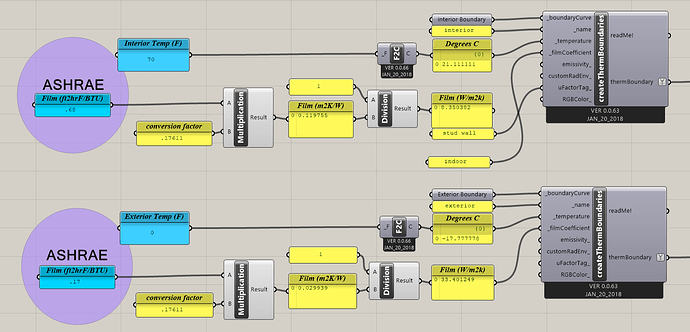

Exterior air film: R-17

Stucco: R-.08

Exterior gyp: R-.56

Frame/cavity: per chart

Interior gyp: R-.56

Interior air film: R-.68

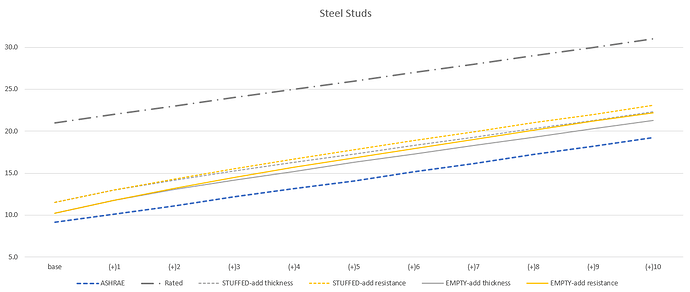

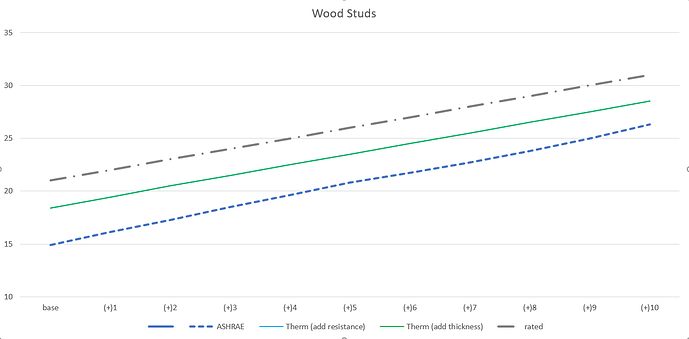

Here’s the ASHRAE chart I tried to replicate

This brought up several questions – I read somewhere that the ASHRAE values come from actual hotbox testing, not math. Was there insulation within the steel stud? What was the conductivity of the steel? How was resistance added? As we know, there are two ways to increase the resistance in the wall:

a. Increase thickness (maintain same R-value/inch)

b. Increase resistance (maintain thickness)

So I tried both options and found that it made a difference in overall R value of the wall, particularly with the metal studs. I left the conductivity of the studs alone at 50 W/mK but did test the two resistance increase methods (mentioned above) and tested scenarios where the metal stud was filled with air instead of insulation. Here’s how I labeled that:

I know all my conversions are right, because I’m able to get the rated R-value that I expected. I found that the empty stud where I added thickness (r-1/in) got closest to ASHRAE values, but it was still R-1 to R-2 ft2hrF/BTU higher than the ASHRAE values. Has anyone had similar experiences? Any wisdom to share? I know that ASHRAE physically tested their assemblies, so there might be some variation there…?

matching ASHRAE materials:

Matching ASHRAE air films:

ASHRAE chart.3dm (490.4 KB)