Wow, thank you again for such a fast respond

I personally work as an energy modeler for half of year, and I don’t have enough experience in Open Studio. And I doubt I would ever became an energy modeler if I couldn’t visualize the energy, as cool as, you did with Ladybug tools

There are curves for basically everything, and the need for individual components appears with each new project.

Energy Plus have curves by default for fans, coils, heat pumps etc., and unfortunately I didnt have enough experience to test so many HVAC components, and see if Honeybe creates curves for that. But I can definitely keep you posted on that.

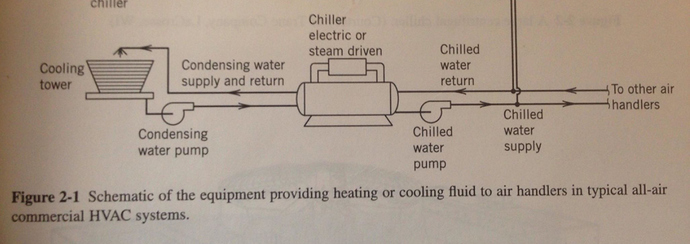

However, I believe, having curves as an input for at least central plant controls, boilers and chillers would be really useful.

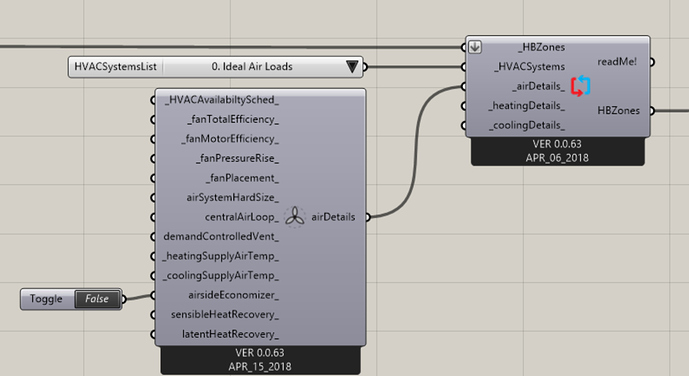

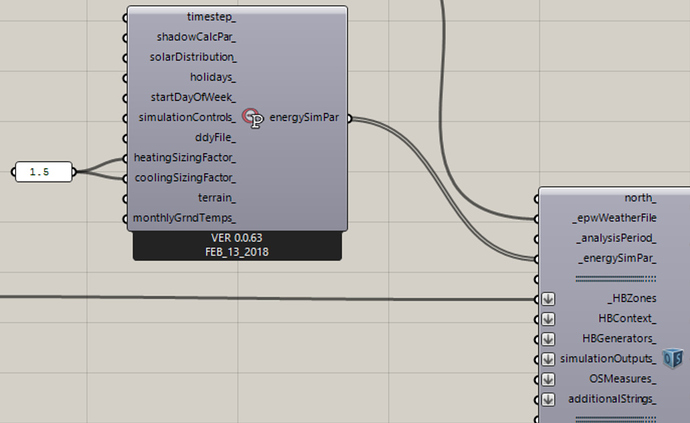

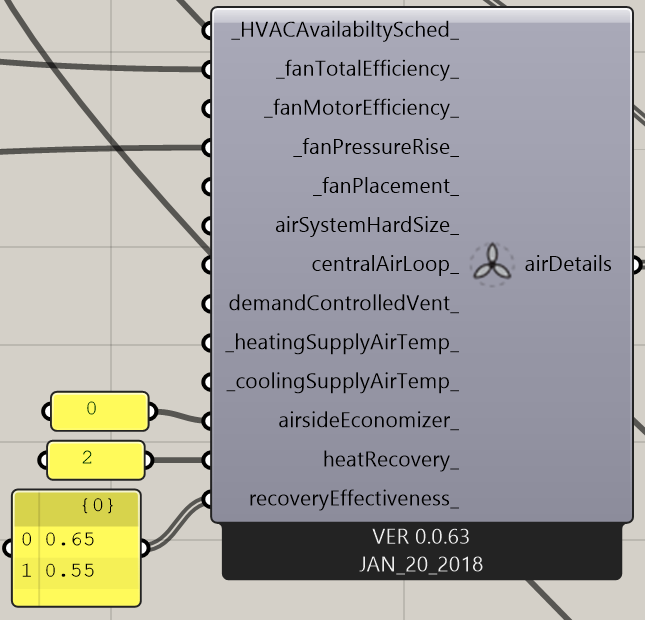

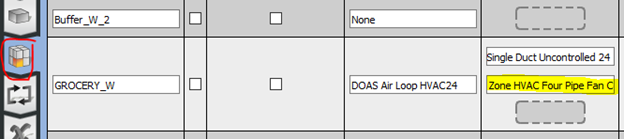

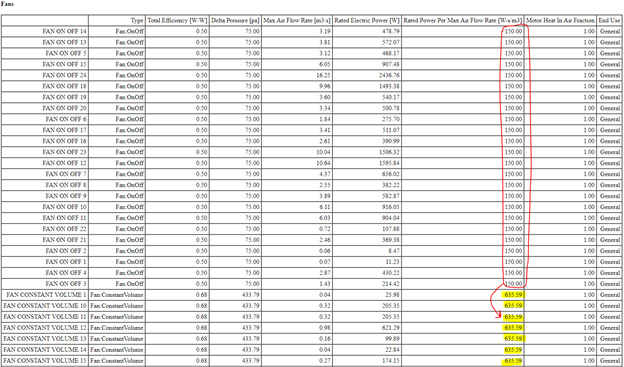

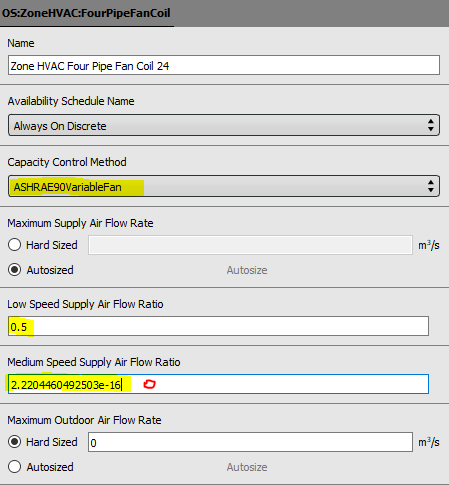

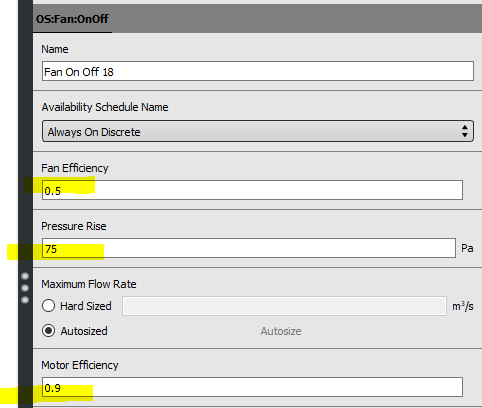

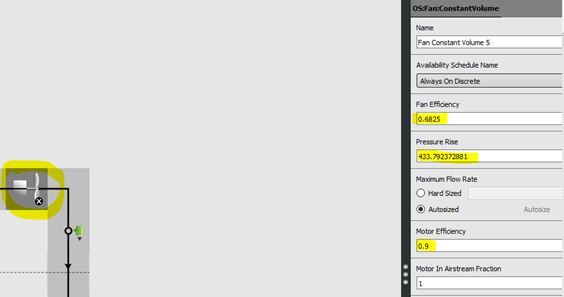

Another thing, that would be great to have, is to have an ability to create hybrid HVAC systems (I believe it is very difficult to code tho). But something like creating variable speed fan in Packaged Single Zone AC, and using this system not only for single zone, but also as a multi-zone. I’m bringing this example because that was my first issue. I was trying to graft/flatten,and other GH magic with HB_zone input, but it still didn’t model as I needed, because Single Zone HVAC is limited by only creating one HVAC per zone, obviously… So I had to do that by hands in OpenStudio, which was a bit painful, but the simulation was successful with multiple zones in Single Zone HVAC. And I believe creating variable speed fans was one of the features in the very early Honeybee releases…

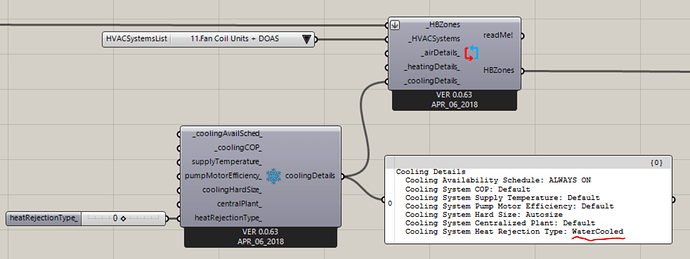

Also, I would really appreciate the ability of changing the default system’s heating/cooling coils on something else. Perhaps there could be a component like “HVAC_system_list” but “Coil_list”. I imagine how many tests there are must be done in order for that to work without crashing… But from my own experience, the heating and cooling coils in the system like “17. Ground Source WSHP + DOAS” can be easily replaced from district heating/cooling to Hot Water Boiler and Absorption Chiller, without errors.

[And perhaps that test can be done by Brute Force, that u described  (sort of cheating)]

(sort of cheating)]

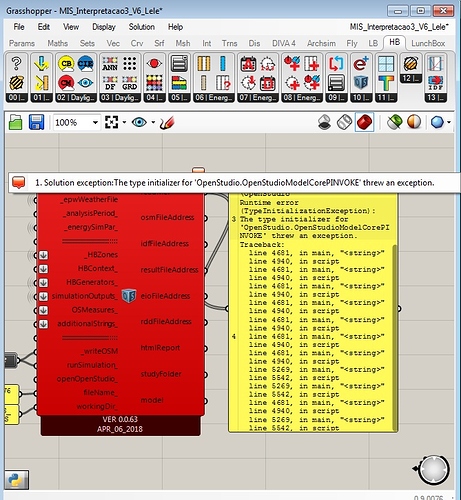

The cool thing about Open Studio is the HVAC interface. (Except, there is no ctrl+c/ctrl+v, or just a simple “search” command). But maybe, instead of doing all of what I just described, it is easier just to use OS interface, but to make it possible to create parametric simulations from already existing OS file, which would involve even the changes in geometry. But I, again, believe or Rhino or OS will crush eventually during the parametric runs…

Anyways, I will keep u posted on glitches and wished  I already have some in my reserve, I just need to find time to find my old models and highlight what was the issue.

I already have some in my reserve, I just need to find time to find my old models and highlight what was the issue.

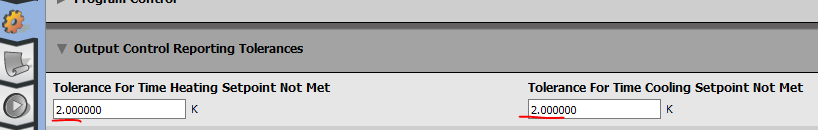

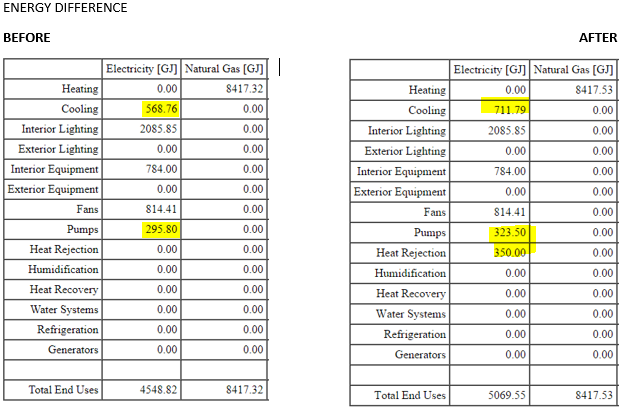

(One of them was disappeared Cooling load, that I was able to solve by simply changing zone program).

!

!

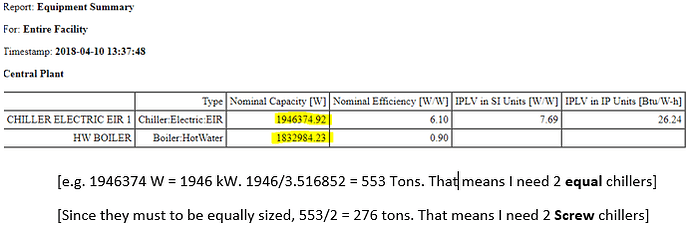

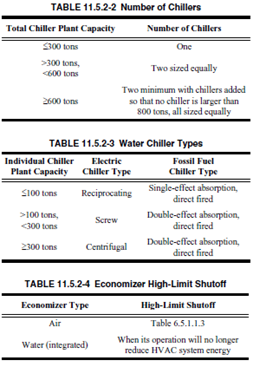

). But in terms of total chiller plant capacity, if it is autosized, there will be a need to add more chillers. Same with Boilers.

). But in terms of total chiller plant capacity, if it is autosized, there will be a need to add more chillers. Same with Boilers.